44 thermal transfer labels definition

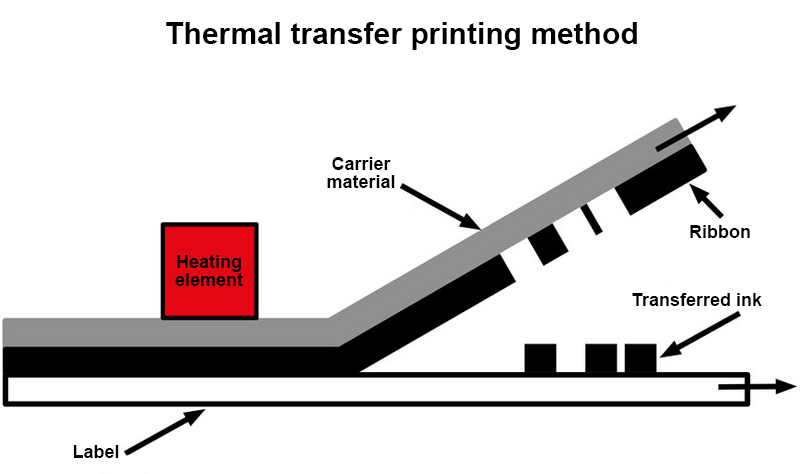

Types of Labels - A Thomas Buying Guide Thermal Transfer Labels. Thermal transfer labels are used for applications where a direct thermal label is inadvisable, perhaps because the labeled product will be stored close to a heat source. Thermal transfer printing uses a ribbon that prints a long-lasting image or words on a label. A thermal printhead applies heat, melting the ribbon's ... What is a Thermal Transfer Printer? - Definition from Techopedia Thermal Transfer Printer: A thermal transfer printer is a category of non-impact printer that uses heat to create an impression on the print media. It uses a carbon ribbon that, upon heating, is moved to the substrate. Unlike some types of printers, a thermal transfer printer can print in color, as the ribbons used can be of different colors ...

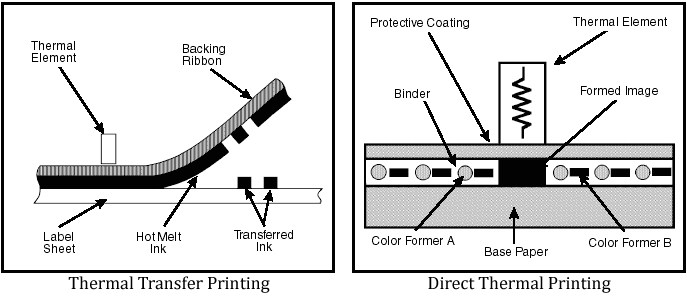

What is a thermal printer? (direct transfer) - Creative Safety Supply Thermal transfer printing occurs by a process that uses heat in order to produce an imagine on paper, a label, or some other such material. The image is created by melting a coating so that it stays glued to the intended material. This technique provides high-quality image printing that can't compare to other on-demand printing options.

Thermal transfer labels definition

Label Definitions and Terms | Perforated Label - I.D. Images Direct Thermal: a material that does not require a ribbon for printing. Heat is applied directly to the label, and a chemical reaction on the face stock causes the label to darken where heat is applied. Receipt printers use direct thermal technology. Think Toner, Inc.: Thermal Transfers Uses and Definition - Blogger Thermal Transfer is a popular printing process particularly used for the printing of designs or identification labels. Thermal transfers are an extremely popular printing process in the industrially developed world. It is especially used for the printing of high quality barcodes. Thermal transfer | inkanto by ARMOR-IIMAK THERMAL TRANSFER DEFINITION, Thermal Transfer printing is a simple, performing and competitive printing technology that enables to print all types of labels and flexible packaging.. Definition, What is Thermal Transfer Printing ? Applications, Thermal Transfer: barcode and packaging printing, Sustainable Performance,

Thermal transfer labels definition. Direct Thermal vs Thermal Transfer Printer | Direct Thermal Transfer Labels What are Thermal Transfer Labels? These thermal transfer printer labels require a ribbon when printing. Both the labels and the ribbon feed through the printer, and the printer applies heat to the ribbon to transfer the wax and resin onto the label (hence the term thermal transfer printer). Direct Thermal vs Thermal Transfer Labels | Diversified Labeling Solutions What Are Thermal Transfer Labels? Thermal transfer labels use ribbons that hold ink to "transfer" the image onto the media. This is done with the same printheads used in direct thermal printing. A lot of the roll media printers are set up to print both T.T. and D.T. The determining factor is whether there is room or a place to hold the ribbon roll. Direct Thermal and Thermal Transfer Printing | Zebra Thermal transfer printing produces long-life image stability. Thermal transfer enables batch or single label printing with virtually no waste. Long-term maintenance costs are low compared to dot matrix, ink jet and laser printing. Thermal transfer technology can print on a nearly unlimited variety of media stock (except multi-form). Définition of thermal transfer printing | inkanto by ARMOR-IIMAK Thermal transfer is a fast printing process that allows the printing of variable data, controlled directly via dedicated software. This software connected to the printer transmits the data and printing information that will make each product unique.

What is Thermal Transfer Printing? | Technicode, Inc. Thermal transfer printing involves melting resin-based ink or wax ribbons onto printing media, which results in a high-quality, long-lasting image. Manufacturers primarily use thermal transfer printing to print labels due to its resistance to moisture and heat that allows for optimal durability. Thermal Transfer vs. Direct Thermal: Five Key Considerations Conversely, thermal transfer printing has thermal ribbon acting as a "buffer" between the print head elements and the label material. Many thermal ribbons are designed with a back-coating that serves to increase print head life by reducing static and friction. This benefit is not possible when direct thermal printing due to the lack of ribbon. Durable Labels for Extreme Hot & Cold Temperatures Our labels are compatible with the following hot applications. Identification labels - Keep labels intact on tools and products that are used in hot water baths, autoclaves, and more.; Barcode labels - Ensure products are scannable at their final destination with heat-proof barcode labels.; Pump and valve labels - Mark water mains, chemical valves, and other pumps to keep communities ... Thermal Transfer vs Direct Thermal - Passion Labels Thermal Transfer: When Thermal Transfer printing, you are using a thermal ribbon, which acts as a buffer between the printhead and label material. Thermal ribbons are designed with an acrylic back-coating, that serves to increase printhead life, by reducing static and friction.

Label Terminology | A to Z Label Terms To Know - Whitlam Thermal Cycle: (Oven, Freezer, or Humidity) Tests the ability of the label to withstand various environmental conditions in a cyclical format. Thermal Transfer Ribbon Testing: Tests the adhesion and quality of thermal transfer ribbon to any given label material. Thermal Transfer Ribbon Types: Wax is the most popular with some smudge resistance. What are Thermal Labels? | Zebra What Are Thermal Labels? Thermal labels use heat to create an image. Thermal transfer uses a thermal ribbon where heat from the printhead releases the ribbon attaching it to the label surface. Direct thermal images are created when heat from the printhead causes components on the label surface to mix causing them to (usually) turn black. Thermal transfer | inkanto by ARMOR-IIMAK THERMAL TRANSFER DEFINITION, Thermal Transfer printing is a simple, performing and competitive printing technology that enables to print all types of labels and flexible packaging.. Definition, What is Thermal Transfer Printing ? Applications, Thermal Transfer: barcode and packaging printing, Sustainable Performance, Think Toner, Inc.: Thermal Transfers Uses and Definition - Blogger Thermal Transfer is a popular printing process particularly used for the printing of designs or identification labels. Thermal transfers are an extremely popular printing process in the industrially developed world. It is especially used for the printing of high quality barcodes.

Label Definitions and Terms | Perforated Label - I.D. Images Direct Thermal: a material that does not require a ribbon for printing. Heat is applied directly to the label, and a chemical reaction on the face stock causes the label to darken where heat is applied. Receipt printers use direct thermal technology.

Thermal Label Printer,ForAngel Thermal Shipping Label Printer, 4×6 Label Printer for Shipping Packages Postage Home Small Business, Compatible with ...

B21/B3S Tab Paper Waterproof PVC Thermal Labels Sticker Paper Supermarket Price Barcode Labels High Definition Thermal Stickers

Post a Comment for "44 thermal transfer labels definition"